Capabilities

Bond Optics offers a wide variety of optical manufacturing capabilities and services including grinding and polishing, glass machining, and optical metrology and inspection services.

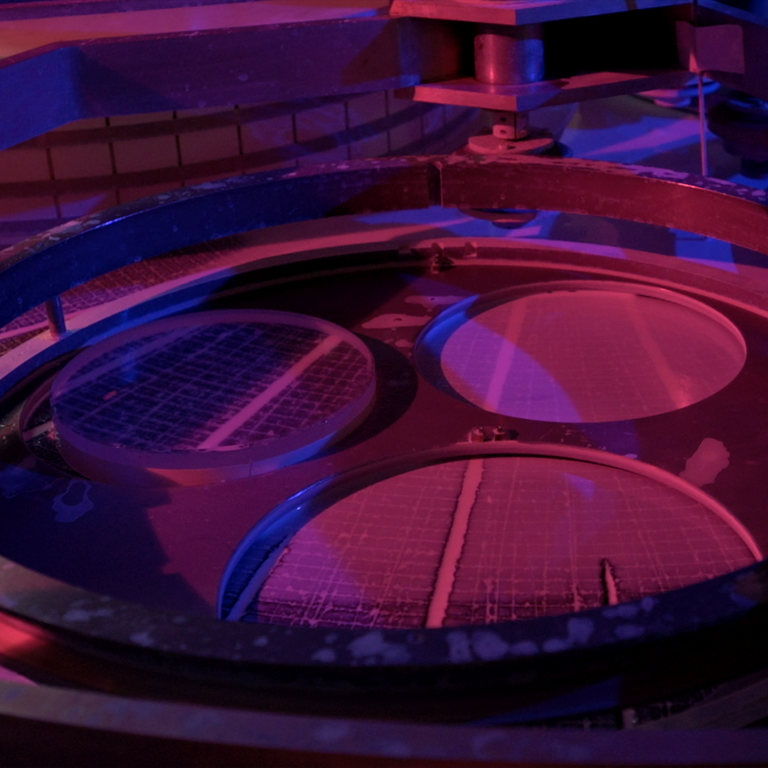

Grinding & Polishing

Bond utilizes single-sided, continuous and double-sided planetary grinding and polishing equipment. Our custom designed continuous polishing machines and proprietary processes developed over six decades, allows our technicians to achieve surface quality to 10/5 scratch/dig, surface roughness down to 3Å RMS and surface flatness down to λ/40 PV.

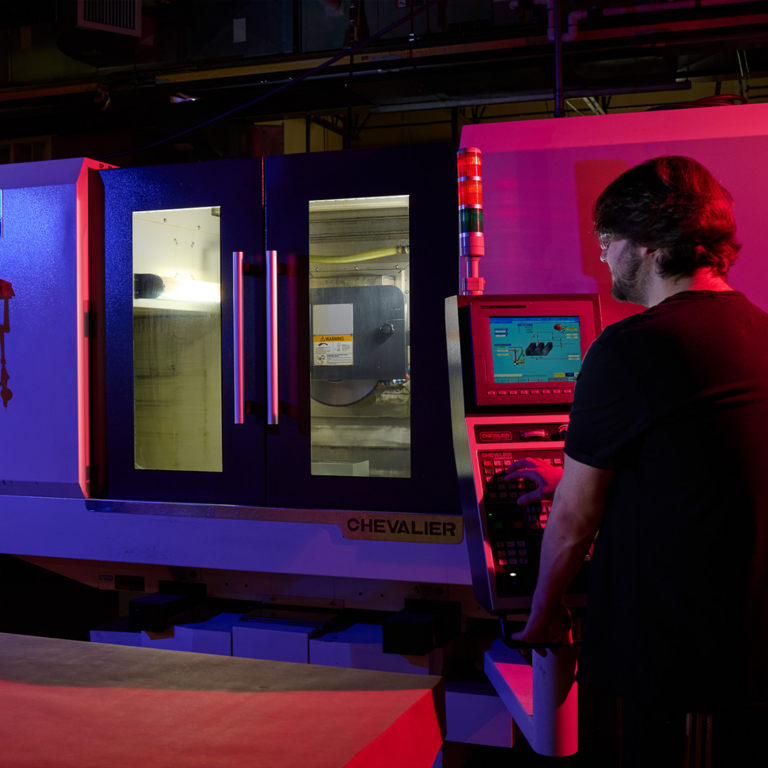

Machining

Our experienced staff of CNC machinists and fabricators employ

state-of-the-art machining methodologies to shape parts with complicated geometries to the tightest of tolerances. Bond possesses an extensive range of specialized equipment, allowing us to optimize processes and tailor our machining to precisely meet your needs.

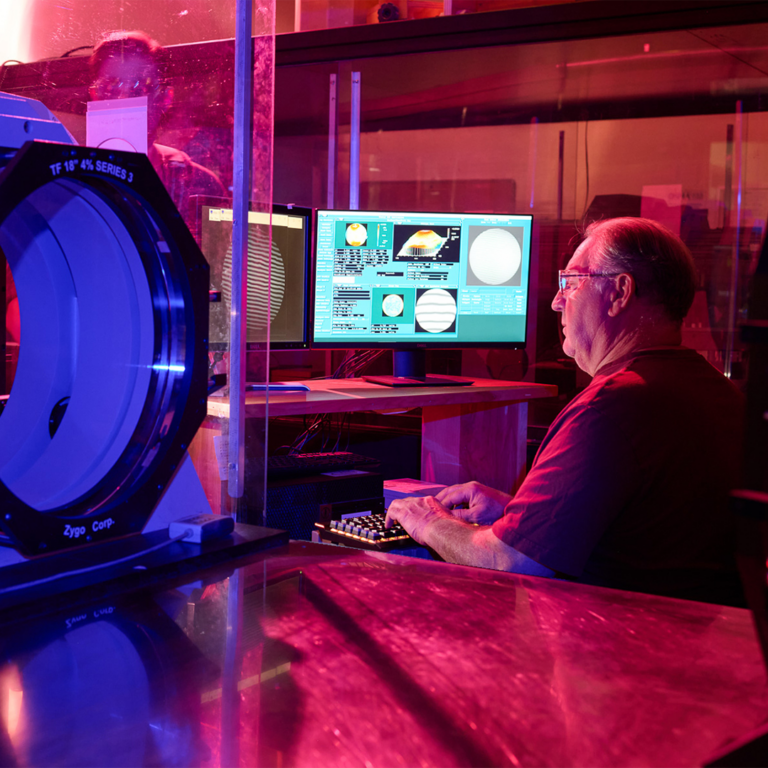

Metrology & Inspection

Bond’s metrology and inspection services guarantee the highest level of quality control. Our comprehensive testing procedures, using advanced interferometers and measurement tools, ensure each optical component meets rigorous precision and performance criteria.

You can’t make what you can’t measure!

Manufacturing Limits

| Specifications* | Prisms | Windows | Beamsplitters | Mirrors |

|---|---|---|---|---|

| Dimensions | 5mm to 300mm | 4mm to 650mm | 6mm to 300mm | 6mm to 650mm |

| Flatness | λ/40 | λ/30 | ||

| Angle Tolerance | 1 arcsec | - | 1 arcsec | - |

| Surface Quality | 10-5 scratch-dig | |||

| Dimensional Tolerance | 0.0125mm | |||

| Parallelism | - | <1 arcsec | ||

| Surface Roughness | 3Å | |||

* Maximum achievable specifications are subject to part geometry

Let's Get Started!

Get in touch with an expert at Bond Optics to help you find the right solution for your organization. From prototype runs to large scale production, no job is too large or too small.